Description

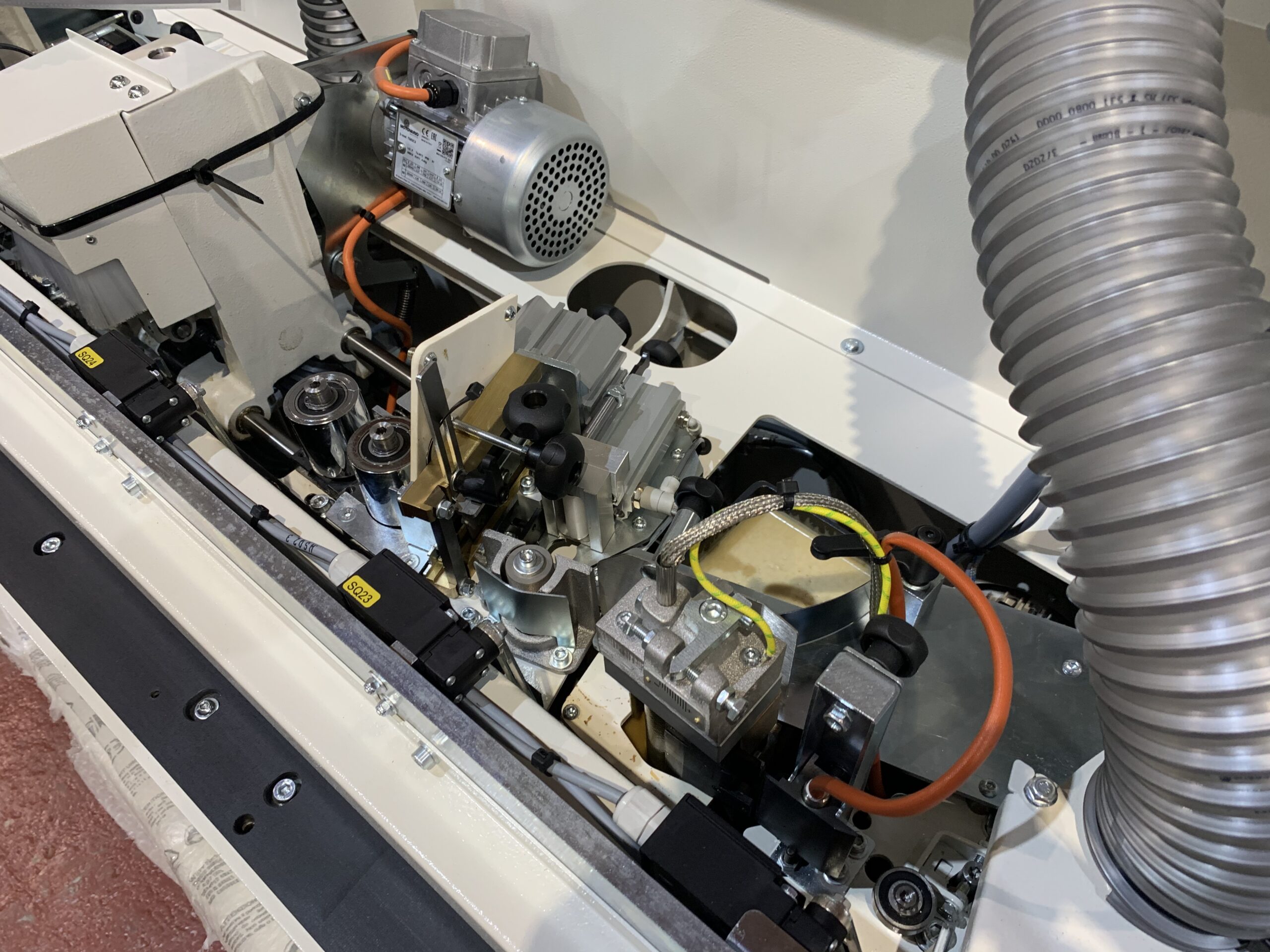

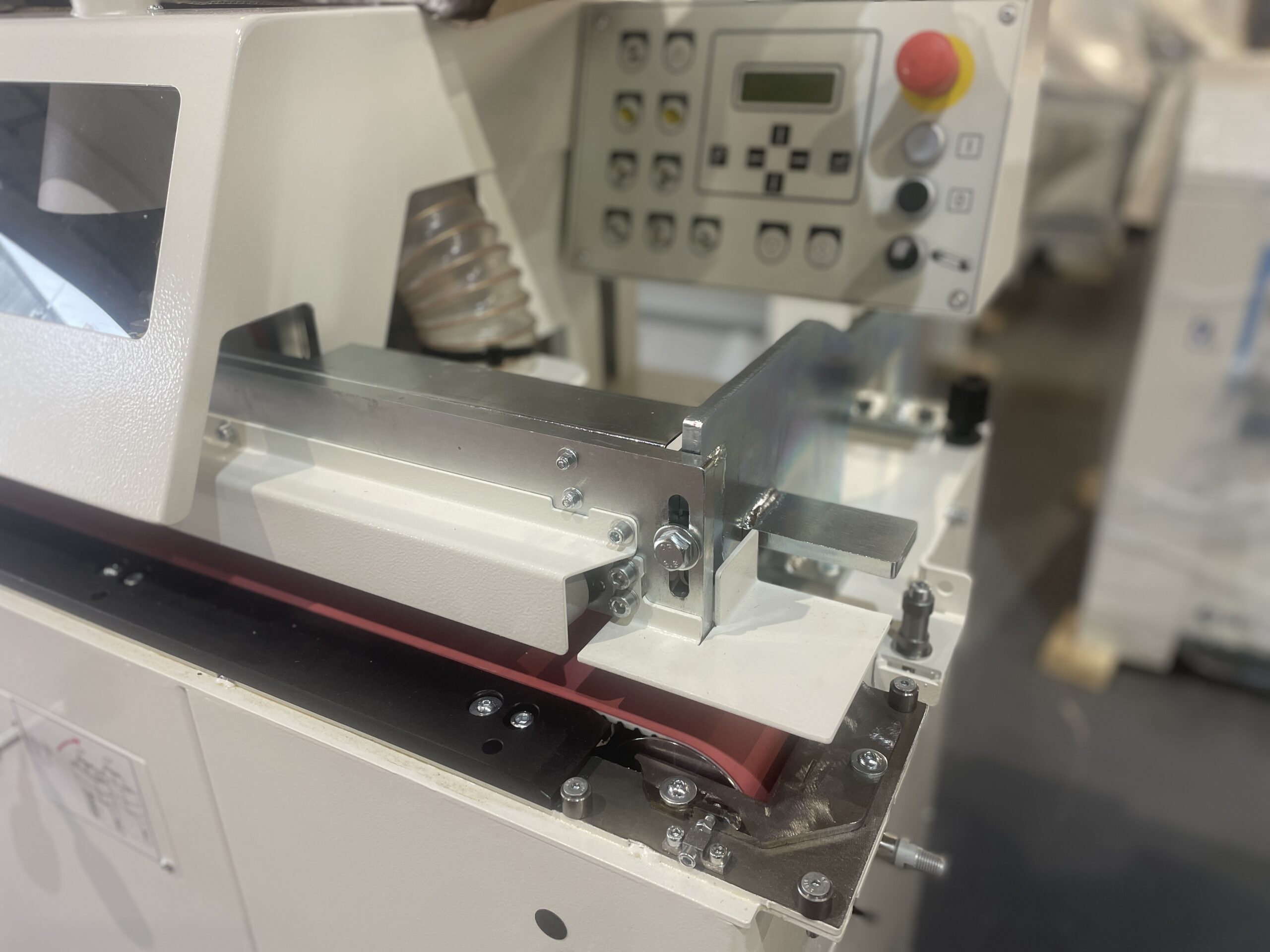

Pre-milling unit.

Panel edge surface without any imperfections before the gluing operation through the removal operation that corrects any panel imperfections caused by the saw cutting process and panel storage. The independent exhaust system ensures the panel cleaning removing dust and chips from the panel. No. 4 different thickness removals: 0,5 / 1 / 1,5 / 2 mm.

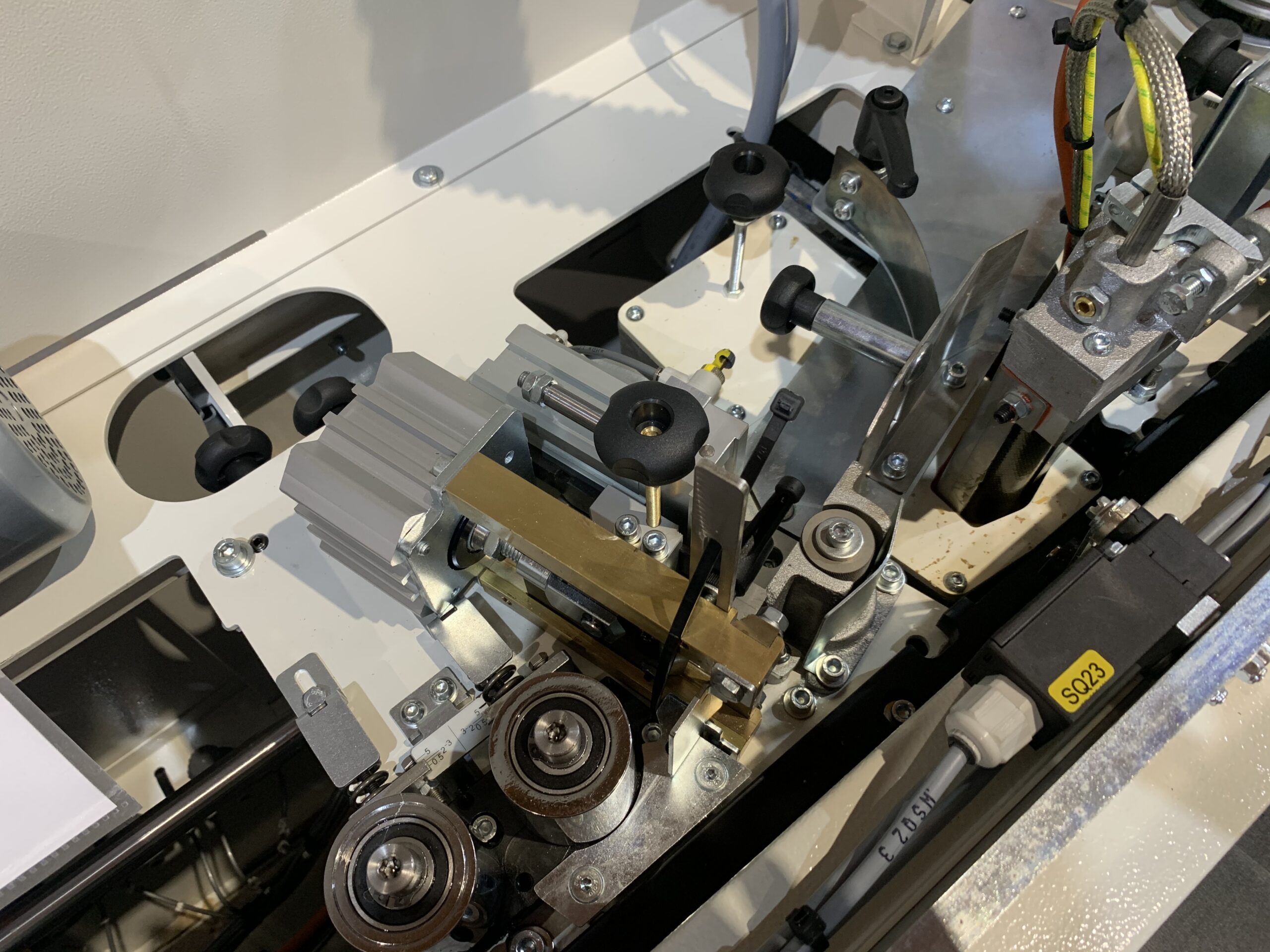

Designed for a perfect finish

The very best finishing of the panel edge is also guaranteed by the panel conveying track (exclusive solution), which prevents the panel having the feed affected by the typical pulses generatedby the pinion of a traditional feed track and ensures a smooth and linear panel movement.

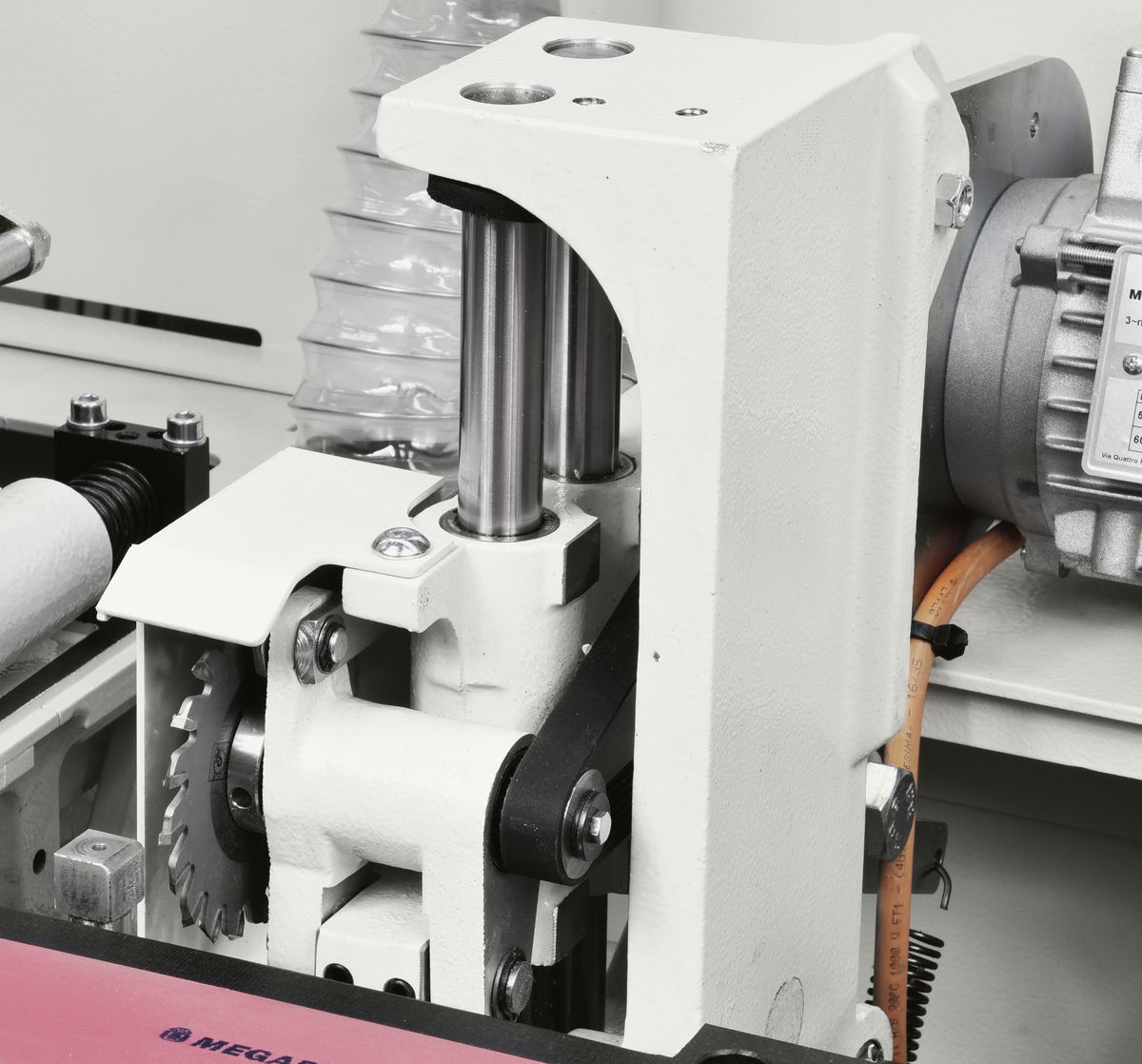

Always precise when cutting

Absolute precision offered by the unit, with a cutter and an independent asynchronous.

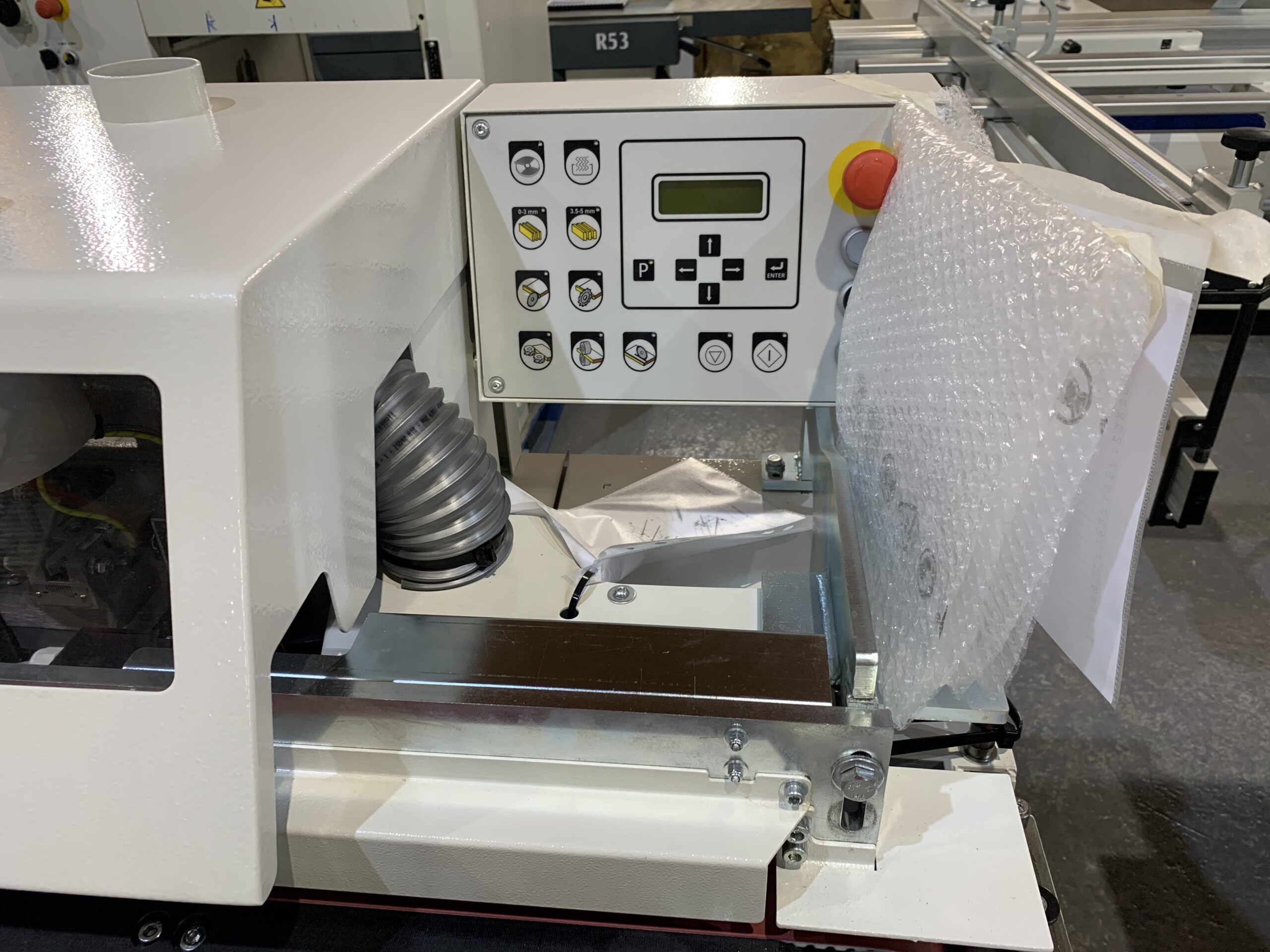

Simple and intuitive

Error-free machining is ensured by the control panel positioned on the front of the machine, that allows an easy selection of all the main functions, among them, the operating units switching on and off. The PLC guides the operator during maintenance, cleaning, diagnostic operations, etc.

Machine in Brief:

Technical data

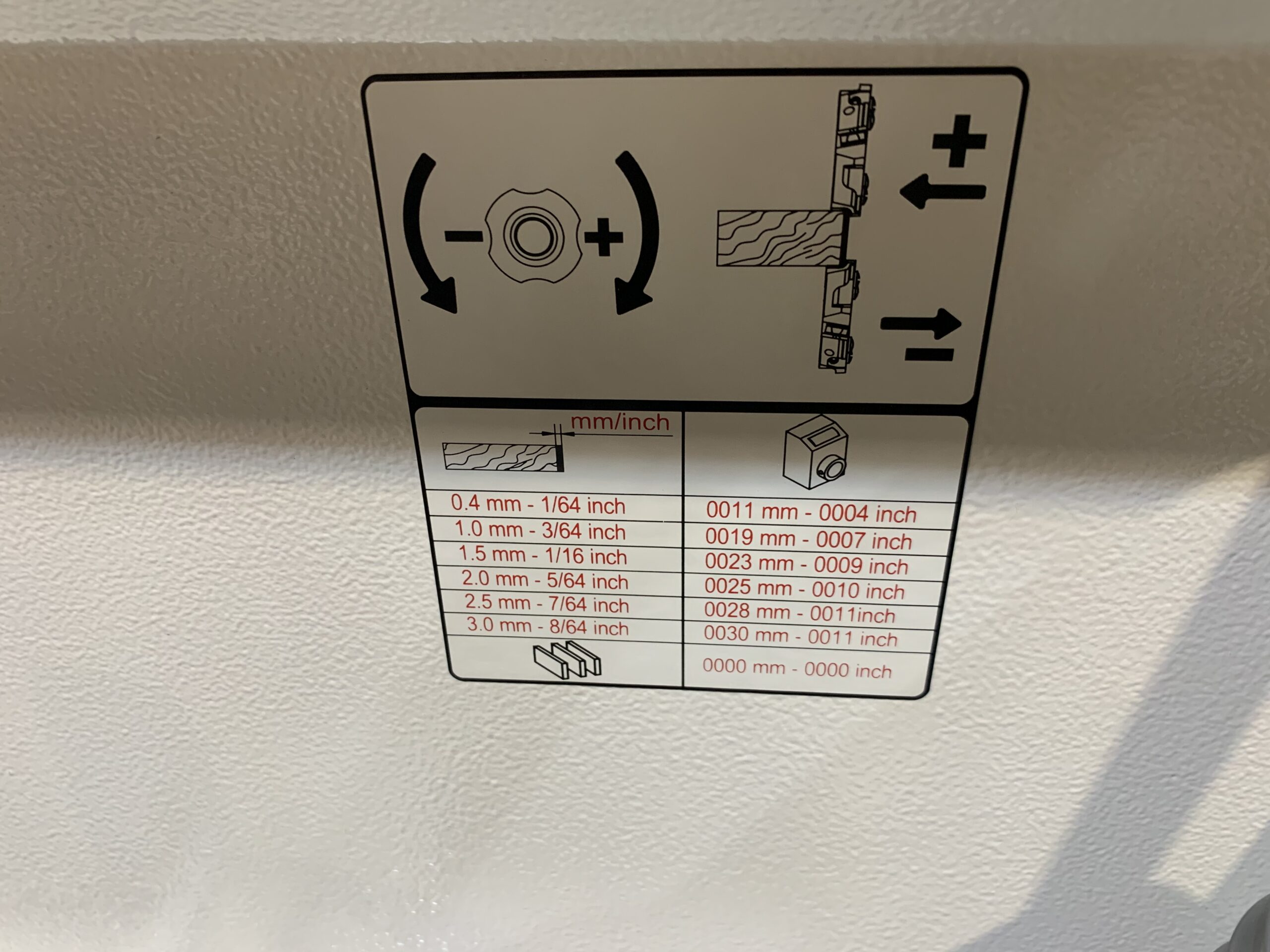

| me 28t | ||

| Work table dimensions | mm | 2800 x 570 |

| Min. ÷ max. thickness of rolled edges | mm | 0,4 ÷ 3 |

| Max. thickness of edges in strips | mm | 5 |

| Min. ÷ max. panel height | mm | 12 ÷ 50 |

| Min. panel length/width | mm | 190/110 |

| Feed speed | m/min | 7 |